XGU-F Series Anti-wear Type Suspension Clamp

Insulated wires can be fixed and left dangling with suspension clamp of the XGU-F type. The "U" shaped product is appropriate for grounding wires, jumpers, and other insulated wire suspension and fastening in overhead electrical lines. The high-strength aluminum alloy used to make the suspension clamp has several benefits, including light weight and ease of installation. It can also effectively resist breakage and displacement of the jumper wire and grounding wire strands, enhancing the line's safety and dependability. Furthermore, the suspension clamp has strong resistance to corrosion and can be used in a variety of challenging conditions.

Feature

1. It is made of materials that are resistant to corrosion, so it can be used in a variety of environments for an extended period of time without experiencing corrosion.

2. Reasonable design, easy and quick installation, saving construction time and cost.

3. It can guarantee stable clamping effect under various operating situations and provide dependable power transfer after rigorous quality control and testing.

Model Specification

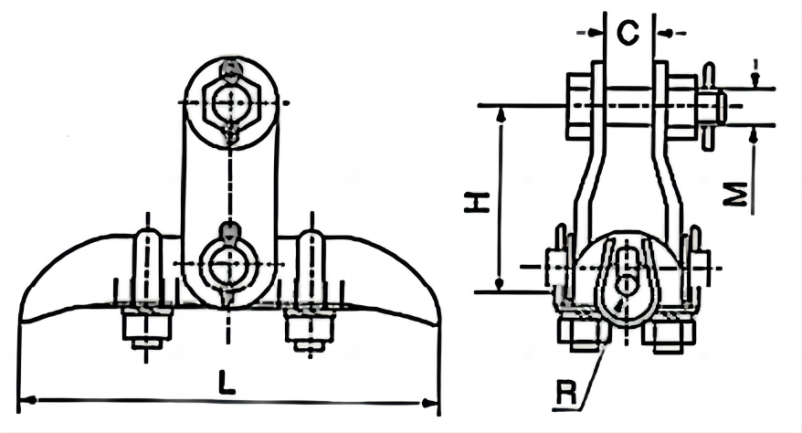

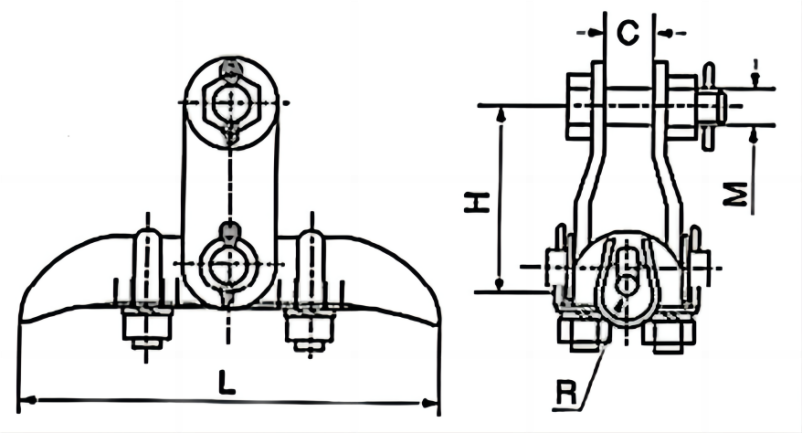

Model | Applicable wire

range (mm)

with wrap | Schematic | Main dimensions

(mm) | Nominal

destruction

load(kN) | Weight

(kg) |

H | L | R | C | M |

XGU-1F | 5.0-7.0 | 1 | 82 | 180 | 4.0 | 18 | 16 | 40 | 1.6 |

XGU-2F | 7.1-13.0 | 103 | 200 | 7.0 | 18 | 16 | 40 | 2.4 |

XGU-3F | 13.1-21.0 | 121 | 220 | 11.0 | 18 | 16 | 40 | 2.5 |

XGU-4F | 21.1-26.0 | 132 | 250 | 13.5 | 19 | 16 | 40 | 4.0 |

XGU-5F | 23.0-33.0 | 140 | 300 | 17 | 20 | 18 | 60 | 4.5 |

XGU-6F | 34.0-45.0 | 155 | 300 | 23 | 20 | 18 | 60 | 5.0 |

XGU-5AF | 23.0-33.0 | 2 | 210 | 300 | 17 | 18 | 16 | 60 | 5.7 |

XGU-6AF | 34.0-45.0 | 225 | 300 | 23 | 18 | 16 | 60 | 6.1 |

XGU-5BF | 23.0-33.0 | 3 | 190 | 300 | 17 | 18 | 16 | 60 | 5.4 |

XGU-6BF | 34.0-45.0 | 205 | 300 | 23 | 18 | 16 | 60 | 5.8 |

XGU-7BF | 45.0-48.7 | 310 | 300 | 26 | 18 | 16 | 60 | 6.4 |

The clamp body and the brackets are made of malleable cast iron, the cotter pins are made of stainless steel, the other parts are made of hot-dip galvanized steel.

Images

Installation Method Of Suspension Clamps

1. Make sure the safety measures are in place, the working area is cleaned up and the required tools and materials are ready.

2. Determine the installation location of the XGU-F Pendant Clamp according to the power line design requirements and actual conditions.

3. Place the XGU-F Suspension Wire Clamps in the installation position correctly and securely fasten the clamps to the bracket or other supporting structure using bolts or other fasteners.

4. Place the power conductor into the clamping groove of the XGU-F Pendant Clamp and adjust as necessary to ensure that the conductor is safely and securely clamped in the clamp.

5. Adjust the tension of the power conductor appropriately according to the design requirements of the power line to ensure that the line is under proper tension.

6. After the installation is completed, carry out inspection and test to ensure that XGU-F Suspension Wire Clamp is firmly installed, the conductor is clamped normally, and the line operates stably.

7. After confirming that everything is in order, complete the installation of XGU-F pendant clamps, and make relevant records and markings.

Please note that the above steps are for reference only, and the actual installation process should be operated according to specific conditions and relevant safety regulations. During the installation process, please make sure the operator has relevant safety skills and experience, and follow the relevant safety regulations.