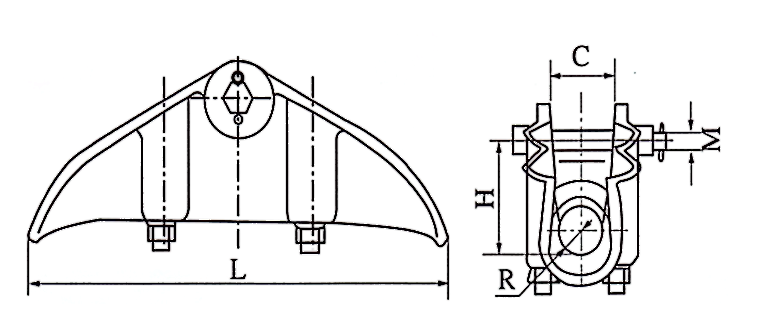

XGT Series Suspension Clamp For Power Transmission And Distribution Lines

In order to ensure the stable operation of transmission lines, XGT type suspension clamps are primarily used for installing insulated wires and fiber optic cable tension in high-voltage transmission lines. These clamps are capable of withstanding external wind pressure, turbulence, and disasters in addition to supporting the wires' self-weight.

Feature

1. Suspension clamps are simple in structure, easy to install, easy to use, easy to dismantle and easy to maintain

2. Special design process is adopted to effectively improve its corrosion and oxidation resistance, and effectively improve the bending strength to meet the actual needs of power transmission and distribution lines.

Model Specification

Model | Applicable wire

range (mm)

with wrap | Main dimensions

(mm) | Nominal

destruction

load(kN) | Weight

(kg) |

H | C | M | R | L |

XGT-1 | 5.0-7.0 | 60 | 18 | 18 | 4.0 | 180 | 40 | 3.3 |

XGT-2 | 7.1-13.0 | 75 | 18 | 18 | 7.0 | 200 | 40 | 4.9 |

XGT-3 | 13.1-21.0 | 75 | 27 | 16 | 11.0 | 220 | 40 | 5.6 |

XGT-4 | 21.1-26.0 | 75 | 27 | 16 | 13.5 | 250 | 60 | 6.5 |

XGT-5 | 23.0-33.0 | 81 | 38 | 16 | 17 | 300 | 60 | 8.7 |

XGT-6 | 34.0-45.0 | 89 | 46 | 16 | 23 | 300 | 60 | 9.8 |

The clamp body and the brackets are made of malleable cast iron, the cotter pins are made of stainless steel, the other parts are made of hot-dip galvanized steel.

Images

Installation Requirements For Suspension Clamps

1. The installation location is at the wire or cable connection point of the power transmission line to ensure that the wire or cable is stable.

2. Installation tools are wire rope, pulley, wrench, pliers, etc. to ensure safe and reliable installation.

3. Installation steps

(1) First clean the installation location and confirm whether the power transmission line meets the relevant safety standards.

(2) Thread the pendant clamp through the wire or cable and place it in the intended location.

(3) With the help of a specific tool such as a wrench or pliers, connect the ends of the pendant wire clamps tightly.

(4) Finally, adjust and increase the tension of the wire or cable by using a pulley to pull it within the safety standards.

4. Installation requires attention to proper operating procedures and safety precautions to ensure the quality of the installation. To ensure the effectiveness of the installation, all equipment on the transmission line should be inspected and maintained periodically.